Arise Manufacturing Infrastructure

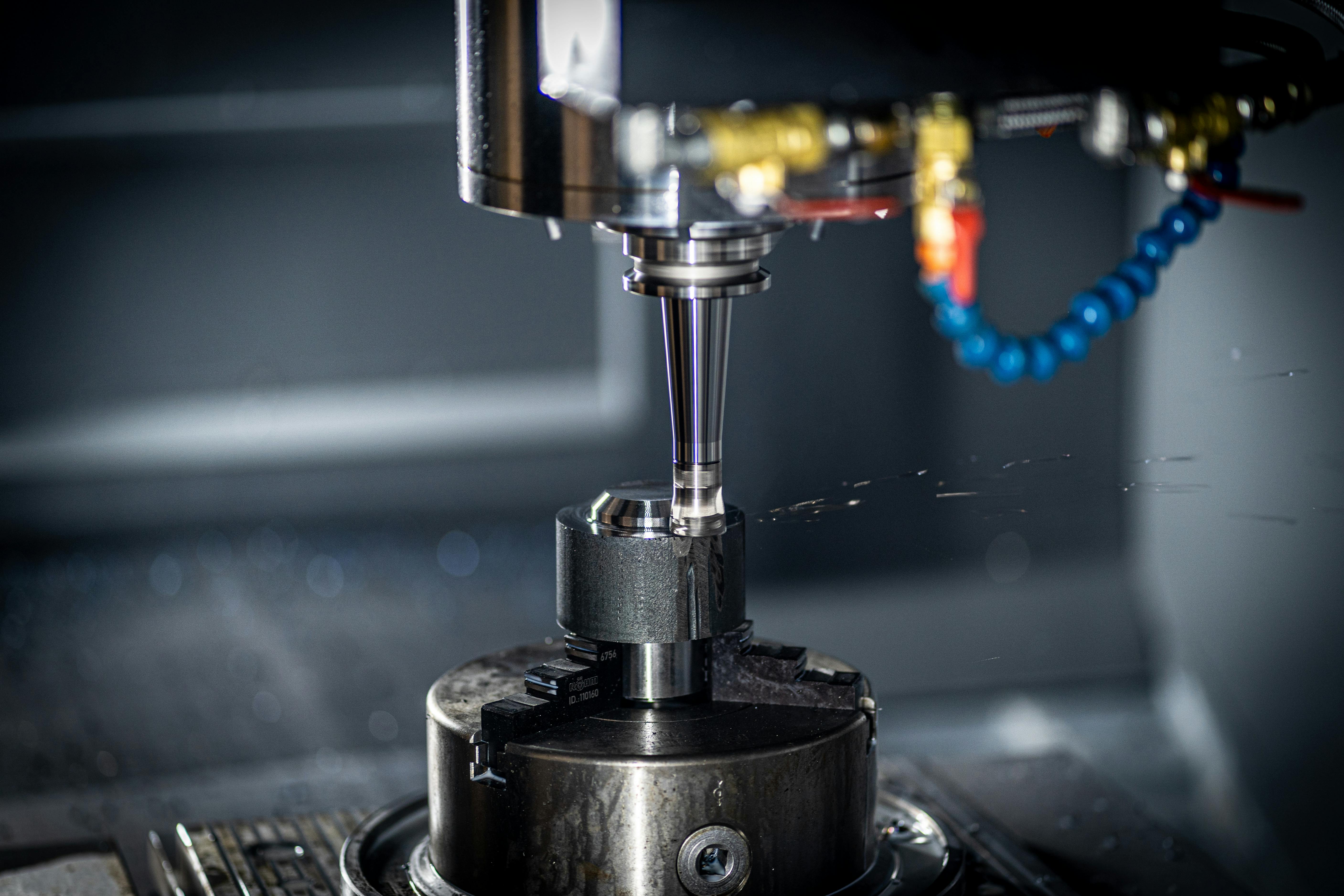

At Arise Machine Tools, our strength lies in a robust, technology-driven infrastructure built to deliver world-class machining performance. Every tool we manufacture goes through a precise combination of advanced machinery, skilled engineering, and stringent quality control. Our facility is designed to handle end-to-end CNC tooling requirements, ensuring consistency, accuracy, and reliability at every stage.

1. Advanced CNC Machining Facility

Our production unit is equipped with state-of-the-art CNC machining centers capable of producing tools with exceptional dimensional accuracy.

- 5-Axis CNC Machining Centers

- High-Precision Tool Grinding Machines

- CNC Lathe Machines

- Surface Grinding & Milling Equipment

2. Precision Tool Grinding Setup

To achieve industry-leading tool sharpness and life, we operate a dedicated tool grinding section featuring:

- CNC spiral flute grinders

- Endmill & slot mill grinding machines

- Carbide & HSS profile grinding systems

- Fully-automated tool grinding workstations

3. Quality Inspection & Metrology Lab

Quality is at the core of everything we do. Our in-house metrology lab includes:

- Profile Projector (Vision Measuring System)

- Digital Height Gauges

- Bore Gauges & Micrometers

- Tool Runout Testing Machines

- Surface Roughness Tester (Ra Measurement)

- Verniers, Dial Gauges, Plug Gauges

4. Heat Treatment & Coating Partners

We maintain strong collaborations with industry-approved heat treatment and PVD/CVD coating units:

- Titanium Nitride (TiN)

- Titanium Aluminium Nitride (TiAlN)

- Diamond Coating for Aluminium

- Special Wear-Resistant Coatings

5. Tool Holder & Assembly Division

A dedicated zone for tool-holding systems ensures compatibility and stability during high-speed machining.

- ER Collet Assembly Stations

- Hydraulic & Shrink-Fit Holder Testing

- CKB/BT/ISO Arbor Assembly

- Balancing & Runout Checking Stations

6. Inventory, Storage & Dispatch Unit

Our warehouse is fully organized with structured inventory management:

- Categorized tool shelves

- Temperature-controlled storage for carbide

- Barcode labeling for easy tracking

- Safe packing zone for export shipments

7. Research, Testing & Development

Innovation drives us forward. Our R&D department focuses on:

- New tool geometry design

- Chip flow optimization

- Wear pattern analysis

- Material compatibility research

- Prototype development & field testing

Committed to Excellence

With our advanced infrastructure, skilled workforce, and strict quality checks, Arise Machine Tools is committed to delivering precision tools that meet the evolving demands of modern manufacturing. Our facility ensures every product is reliable, consistent, and built for high-performance machining.